Our Consulting Services around “Supply Chain Mapping”

Supply Chain Mapping

Supply·Chain·Map /sə’plie-chayn-map noun/ 1 the sequence of processes involved in the production and distribution of a commodity 2 a representation of the physical, informational and financial flows between a company and its suppliers to produce and/or distribute a specific product or service to the final buyer 3 a representation of the steps it takes to get the product or service from its original state to the customer. Mapping verb trans/ 1a to make a map of (something). b to delineate (something) as if on a map.

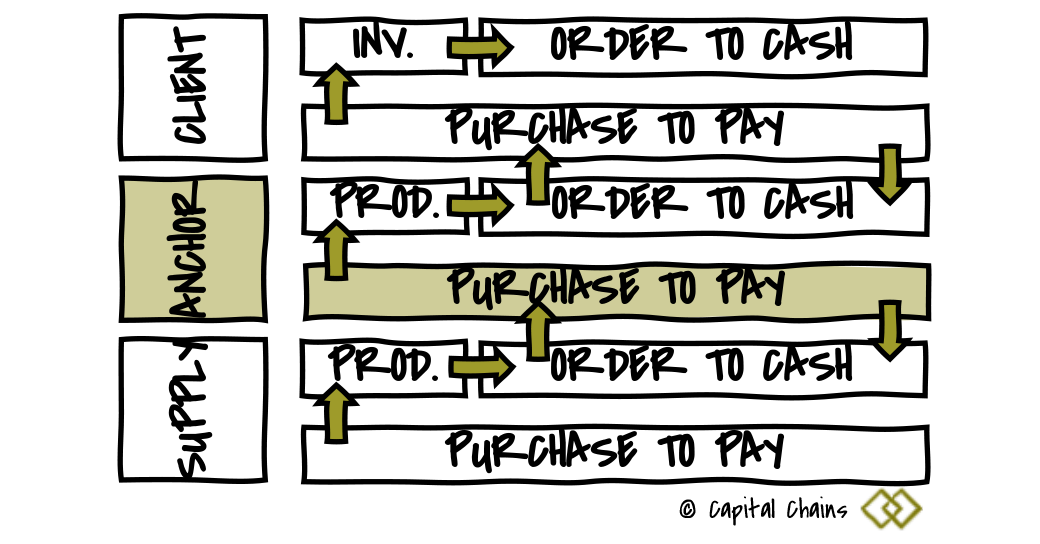

The SCF Supply Chain Mapping exercise by Capital Chains supports in creating an overview of the (extended) supply chain of an anchor corporate. By visualising what the supply chain looks like, it allows us to identify and segment both (first tier) suppliers and (first tier) customers.

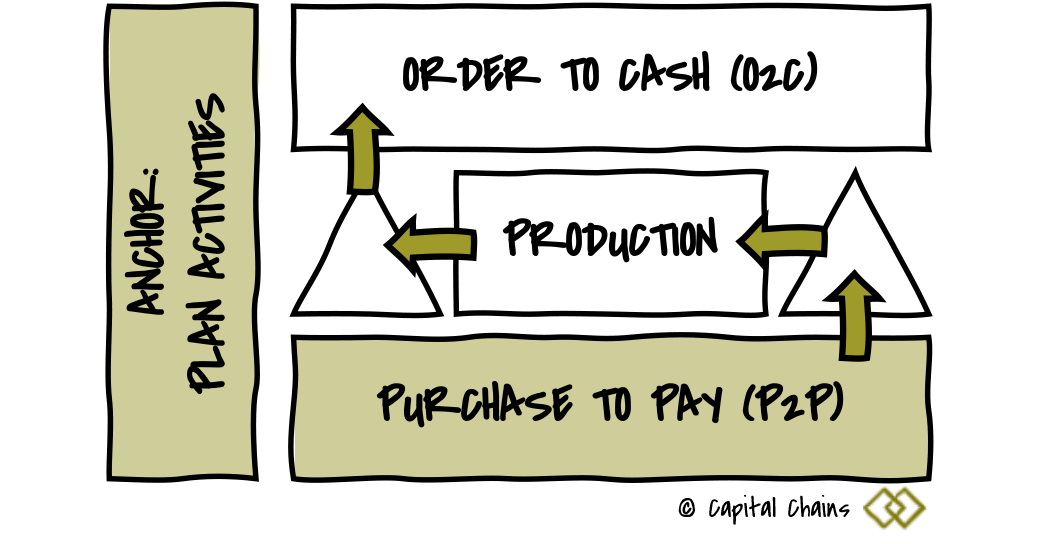

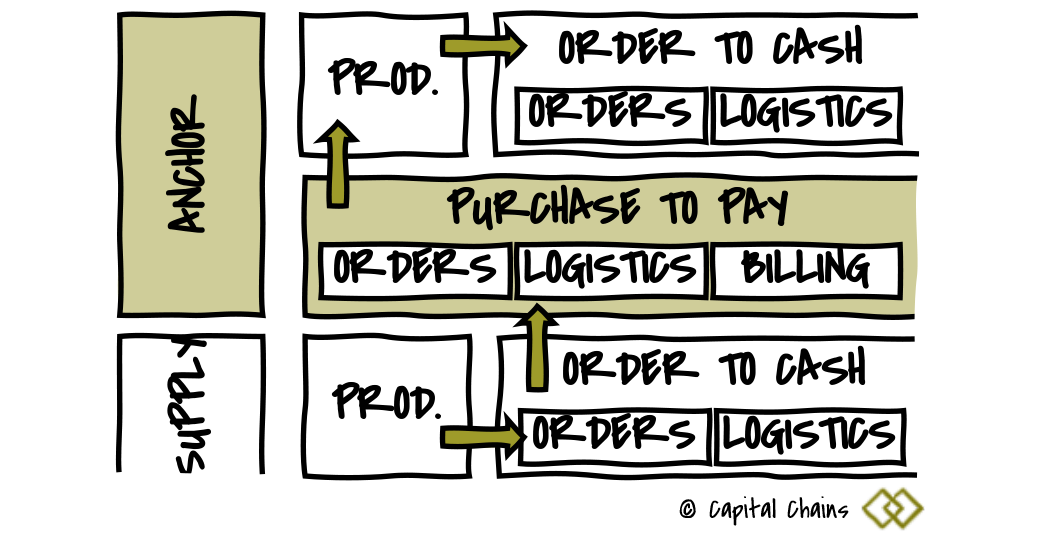

The mapping exercise starts with the alignment of the anchor’s Order-to-Cash (O2C) and Purchase-to-Pay (P2P) process with similar processes for related supply chain partners. With the inclusion of these other supply chain partners, the anchor is able to create a full picture of the end-to-end supply chain. This picture highlights the node interconnectivity on three levels: physical, financial and information flows.

Subsequently, bottlenecks, (financial) constraints, challenges, and opportunities can be mapped on top of the supply chain map. Based on the ‘colouring’ of the initial map, practical interpretations can be distilled. Together with the anchor, areas for improvement are selected and potential solutions can be mapped. Addressing these supply chain needs holds the promise of increasing supply chain reliability, stability and ultimately profitability.

The final step of the supply chain mapping is to quantify the business case. The business case includes a financial model with associated revenues and costs, portfolio sizing, and number of supply chain partners that will be included.