Welcome to FabriCo, the leading sustainable textile company based in Texland. Our mission is to provide high-quality textile products to customers around the world, while also creating job opportunities and supporting economic development in our local community.

FabriCo is a subsidiary of Mo-Group, founded by the Mohammed family in 1956. Mo-Group has its roots in home decoration and FabriCo was launched in 1998 to expand the group’s offerings into the textile industry.

At FabriCo, we specialize in the production of a wide range of textiles, including fabrics for home furnishings, restaurants and hotel textiles, outdoor, and industrial applications. Our state-of-the-art manufacturing facilities use the latest technology and equipment to ensure that our products meet the highest standards of quality and durability.

We are committed to sustainability and environmental responsibility, and we use eco-friendly materials and production methods wherever possible. Our team of expert designers and technicians works closely with customers to create custom solutions that meet their specific needs and requirements.

In addition to our textile production capabilities, we also offer a range of value-added services such as product design, prototyping, and testing. Our experienced team is dedicated to providing exceptional customer service and support at every stage of the production process.

At FabriCo, we believe in giving back to our community, and we are proud to support local charities and initiatives that promote economic development and social welfare. We also provide training and education opportunities for our employees to help them develop new skills and advance their careers.

Thank you for considering FabriCo for your textile needs. We look forward to working with you to create high-quality, sustainable, and socially responsible products that meet your needs and exceed your expectations.

Our Partnerships

Our Partnerships

At FabriCo, we understand the importance of strong relationships with our supply chain partners, including both our suppliers and clients. We recognize that our success is intertwined with the success of those we work with, and we are committed to building long-term, mutually beneficial partnerships.

On the supplier side, we work with a network of trusted partners who provide us with the raw materials and components we need to manufacture our products. We prioritize working with suppliers who share our commitment to sustainability and ethical business practices, and we conduct regular audits to ensure compliance with our standards. We also provide our suppliers with training and resources to help them improve their own sustainability and social responsibility practices.

On the client side, we work closely with a diverse range of businesses, from small startups to multinational corporations, to create custom solutions that meet their unique needs and requirements. We value open communication and collaboration with our clients, and we strive to build long-term relationships based on trust, reliability, and quality.

We understand that our clients rely on us to deliver products that meet their specifications and timelines, and we take this responsibility seriously. Our customer service team is dedicated to ensuring that our clients are satisfied with their orders, and we are always available to answer questions or address concerns.

At FabriCo, we believe that our supply chain partners are essential to our success, and we are committed to working together to create a more sustainable, ethical, and responsible textile industry.

Our Products:

Our Products:

FabriCo specializes in producing high-quality, sustainable, and socially responsible textile products. The company offers a wide range of products to meet the needs of its clients in the textile industry, including:

- Upholstery fabrics for furniture

- Curtains and drapes for homes and businesses

- Bedding and linens for homes and hotels

- Tablecloths and napkins for restaurants and event venues

- Decorative pillows and cushions for homes and businesses

- Towels and bathrobes for hotels and spas

- Outdoor fabrics for patio furniture and umbrellas

- Medical textiles for hospitals and healthcare facilities

- Automotive textiles for cars and other vehicles

- Industrial textiles for various applications such as filtrations, insulation, and packaging

FabriCo is constantly expanding its product offerings to meet the evolving needs of its clients.

Financial Metrics

Financial Metrics

| Assets (in m USD) |

2020 | 2021 | 2022 |

| Property, plant, and equipment | 65,0 | 70,0 | 83,0 |

| Inventory | 10,0 | 12,0 | 14,9 |

| Accounts Receivable | 23,9 | 26,0 | 30,1 |

| Other Assets | 11,9 | 10,8 | 10,1 |

| Cash and Cash Equivalents | 12,1 | 14,2 | 9,9 |

| Total Assets | 122,9 | 133,0 | 148,0 |

| Equity and Liabilities (in m USD) |

2020 | 2021 | 2022 |

| Equity | 80,1 | 87,9 | 90,2 |

| Long-term Debt | 19,9 | 22,1 | 29,8 |

| Short-term Debt | 8,0 | 8,5 | 13,0 |

| Accounts Payable | 11,1 | 10,8 | 10,0 |

| Other Liabilities | 3,8 | 3,7 | 5,0 |

| Total Equity and Liabilities | 122,9 | 133,0 | 148,0 |

| Profit and Loss (in m USD) |

2020 | 2021 | 2022 |

| Sales | 145,0 | 153,0 | 165,0 |

| COGS | 60,8 | 64,4 | 72,6 |

| Gross Profit | 84,2 | 88,6 | 92,4 |

| Operating Expenses | 61,6 | 65,6 | 73,4 |

| Operating Income | 22,6 | 23,0 | 19,0 |

| Interest Expenses | 3,5 | 3,7 | 4,5 |

| Depreciation | 3,0 | 3,3 | 3,5 |

| Profit before Tax | 16,1 | 16,0 | 11,0 |

| Taxes | 5,6 | 5,6 | 3,8 |

| Net Profit | 10,5 | 10,4 | 7,2 |

Benchmark Data

Benchmark Data

Société de Textile:

Annual Revenue : 480 million USD

COGS as a % of sales : 39%

Accounts receivable (AR) balance : 59 million USD

Accounts payable (AP) balance : 54 million USD

Inventory balance : 32.2 million USD

Équipe Mocote:

Annual Revenue : 354 million USD

COGS as a % of sales : 41%

Accounts receivable (AR) balance : 47.4 million USD

Accounts payable (AP) balance : 34.8 million USD

Inventory balance : 22.3 million USD

TextilTexland:

Annual Revenue : 85 million USD

COGS as a % of sales : 47%

Accounts receivable (AR) balance : 17.6 million USD

Accounts payable (AP) balance : 11 million USD

Inventory balance : 11 million USD

CotonRoyal:

Annual Revenue : 100 million USD

COGS as a % of sales : 48%

Accounts receivable (AR) balance : 22 million USD

Accounts payable (AP) balance : 7 million USD

Inventory balance : 9.5 million USD

Research Note on the Textile Sector

Research Note on the Textile Sector

Textile companies in Texland are facing numerous challenges when it comes to financial inclusion and the ability to transition towards more sustainable production practices. Texland has a thriving textile industry, which accounts for a significant portion of the country’s GDP and employs a large number of people. However, the industry is facing a number of issues that are impeding its growth and development, including financial constraints and sustainability concerns.

One of the main difficulties textile companies face in Texland is access to financing. Many companies in the sector are small and medium-sized enterprises (SMEs), which often struggle to secure financing from traditional lenders due to lack of collateral, insufficient credit history, or high-risk perception. This lack of access to financing can prevent these companies from investing in new technology, upgrading their production facilities, or expanding their operations, which ultimately hinders their competitiveness in the market.

Another major challenge for textile companies in Texland is the need to transition towards more sustainable production practices. The industry is one of the most water-intensive in the world, and many textile companies struggle to meet the country’s growing demand for water while maintaining sustainable practices. Moreover, textile production generates significant amounts of waste and pollutants, which can have negative impacts on the environment and public health. Consumers are increasingly demanding environmentally friendly and socially responsible products, and textile companies that fail to adopt sustainable practices risk losing market share. However, transitioning towards sustainable practices often requires significant investments in new equipment, training, and certification, which can be difficult for SMEs to manage without access to financing.

Despite these challenges, there are opportunities for textile companies in Texland to overcome these difficulties and transition towards more sustainable production practices. One potential solution is to invest in sustainable technologies, such as water recycling systems, energy-efficient machinery, and non-toxic dyes. These investments can help companies reduce their environmental footprint and improve their long-term sustainability.

Another potential solution is to leverage new financing models, such as impact investing and microfinance, to provide SMEs with access to capital. Impact investors are increasingly looking to invest in sustainable businesses, and microfinance institutions can provide SMEs with access to credit and financial services that they may not be able to secure from traditional lenders.

In conclusion, textile companies in Texland face significant challenges when it comes to financial inclusion and sustainability. However, with the right investments in technology and financing, these companies can overcome these challenges and position themselves for long-term success in a rapidly changing market. By adopting sustainable practices and leveraging innovative financing models, textile companies in Texland can not only improve their competitiveness, but also contribute to a more sustainable and socially responsible industry.

Feedback from First Client Meetings

Feedback from First Client Meetings

As the head of procurement at FabriCo, I am responsible for sourcing high-quality, sustainable, and socially responsible raw materials from suppliers in Texland. While there are many suppliers in the country that meet our standards, we are also facing several challenges in our dealings with suppliers. One of the main challenges we are facing is the availability of raw materials. Texland is heavily dependent on imports for many of the raw materials used in the textile industry, and this can result in fluctuations in supply and pricing. We are constantly monitoring market conditions and working closely with our suppliers to manage these risks.

Another challenge we are facing is the need to maintain consistent quality standards across our supply chain. We work with suppliers of various sizes and capabilities, and ensuring that they meet our quality standards can be a challenge. We are constantly conducting audits and quality checks to ensure that our suppliers are delivering products that meet our requirements.

In addition, we are facing challenges related to sustainability and social responsibility. We are committed to working with suppliers who share our values and are dedicated to ethical business practices. However, not all suppliers meet our standards, and we must carefully vet each supplier to ensure that they are operating in a sustainable and socially responsible manner.

Finally, we are facing challenges related to logistics and transport. Texland is a large country with many remote areas, and this can make it difficult to transport raw materials and finished products. We are working closely with our logistics partners to find efficient and cost-effective transport solutions that meet our needs and support our sustainability goals.

Despite these challenges, we remain committed to working with suppliers in Texland and building strong, long-term relationships that benefit both parties. We are constantly exploring new ways to improve our supply chain and optimize our procurement processes, and we are confident that we can overcome these challenges and continue to deliver high-quality, sustainable, and socially responsible textile products to our customers.

As the head of finance at FabriCo, I am responsible for managing the company’s financial performance in Texland. While we have a strong presence in the market, we are also facing several challenges that are impacting our financial performance.

One of the main challenges we are facing is the access to financing for our supply chain partners. They often struggle to secure financing from traditional lenders due to lack of collateral or insufficient credit history, and as a result we see clients paying late, as well as suppliers requiring earlier payments to manage their credit limits or ability to deliver in general as they have limited or no access to working capital.

As FabriCo’s working capital has taken a significant turn the wrong direction, with actual payment terms on the sales side rising, inventory buildup to manage the lower delivery reliability in the global market, and the need to pay suppliers faster. In combination with general market conditions (rising interest rates and costs) this has caused the profitability to take a hit. This limits our ability to invest in new technology, upgrade our facilities, or expand our operations, which ultimately hinders our competitiveness in the market.

Another challenge we are facing is the need to manage costs and improve efficiency across our operations. The textile industry is a highly competitive and cost-sensitive market, and we need to constantly monitor our expenses and find ways to reduce costs without compromising on quality. We are constantly exploring new technologies and production methods that can help us improve efficiency and reduce costs. To ensure the different departments are aligned, senior management has put new KPIs in place at the beginning of the year, making working capital targets part of performance reviews for all teams and individuals.

Despite these challenges, we remain committed to growing our business in Texland and delivering value to our shareholders, and we are confident that we can overcome these challenges and continue to grow and succeed in the market.

As the account payables team at FabriCo, we are responsible for ensuring that all invoices from suppliers are processed accurately and on time. While we strive to maintain a smooth and efficient process, we are currently facing several challenges that are impacting our operations.

One of the main challenges we are facing is late invoicing by some suppliers. These suppliers are not sending us invoices in a timely manner, which can create delays in our payment processing and impact our relationships with these suppliers. We are working closely with these suppliers to encourage them to send us their invoices in a timely manner, and we are also exploring ways to automate the invoicing process to improve efficiency.

Another challenge we have faced is longer approval terms for invoices. Due to our internal approval processes, some invoices took longer to process than others, which resulted in delayed payments to suppliers. We have worked hard to streamline our approval processes and reduce the time it takes to approve invoices, while still ensuring that all invoices are thoroughly reviewed and approved in accordance with our policies.

Finally, we are facing inbound questions from suppliers on invoice status. Some of our suppliers are reaching out to us to check on the status of their invoices, which can be time-consuming and can also indicate that there may be issues with our payment processing system. We are currently working on improving our communication with suppliers and provide more visibility into the status of their invoices, so that they are informed and can plan accordingly. This is an IT incentive with supplier portals.

As the IT team at FabriCo, we are responsible for ensuring that our systems and infrastructure support the needs of the business and enable us to remain competitive in the market. Over the past year, we have made significant progress in upgrading and improving our technology capabilities, which has enabled us to achieve several key milestones.

First, we successfully completed a major upgrade to our ERP system last year. This upgrade has enabled us to streamline our business processes, improve data accuracy and accessibility, and enhance our reporting capabilities. With the new ERP system in place, we are better positioned to make informed business decisions and respond quickly to changing market conditions.

In addition to the ERP upgrade, we are also introducing supplier portals that will enable our suppliers to manage their orders and invoices online. These portals will improve the efficiency of our procurement processes and enhanced our communication with suppliers, which should result in improved supplier relationships and a significant reduction in inbound queries for the account payables department.

Finally, we have also implemented the ability to connect to third party systems using real time APIs. This capability has enabled us to integrate with our logistics and transportation partners, as well as our financial institutions, in real-time. This has improved our visibility and control over our supply chain and financial operations, which has enabled us to make better decisions and respond more quickly to changes in the market.

As we continue to invest in our technology capabilities, we remain committed to leveraging the latest tools and solutions to improve our business operations and enhance our customer experience. We are constantly exploring new opportunities and strategies to improve our IT systems and infrastructure, and we are confident that these investments will enable us to remain competitive and achieve our business goals.

Production Process

Production Process

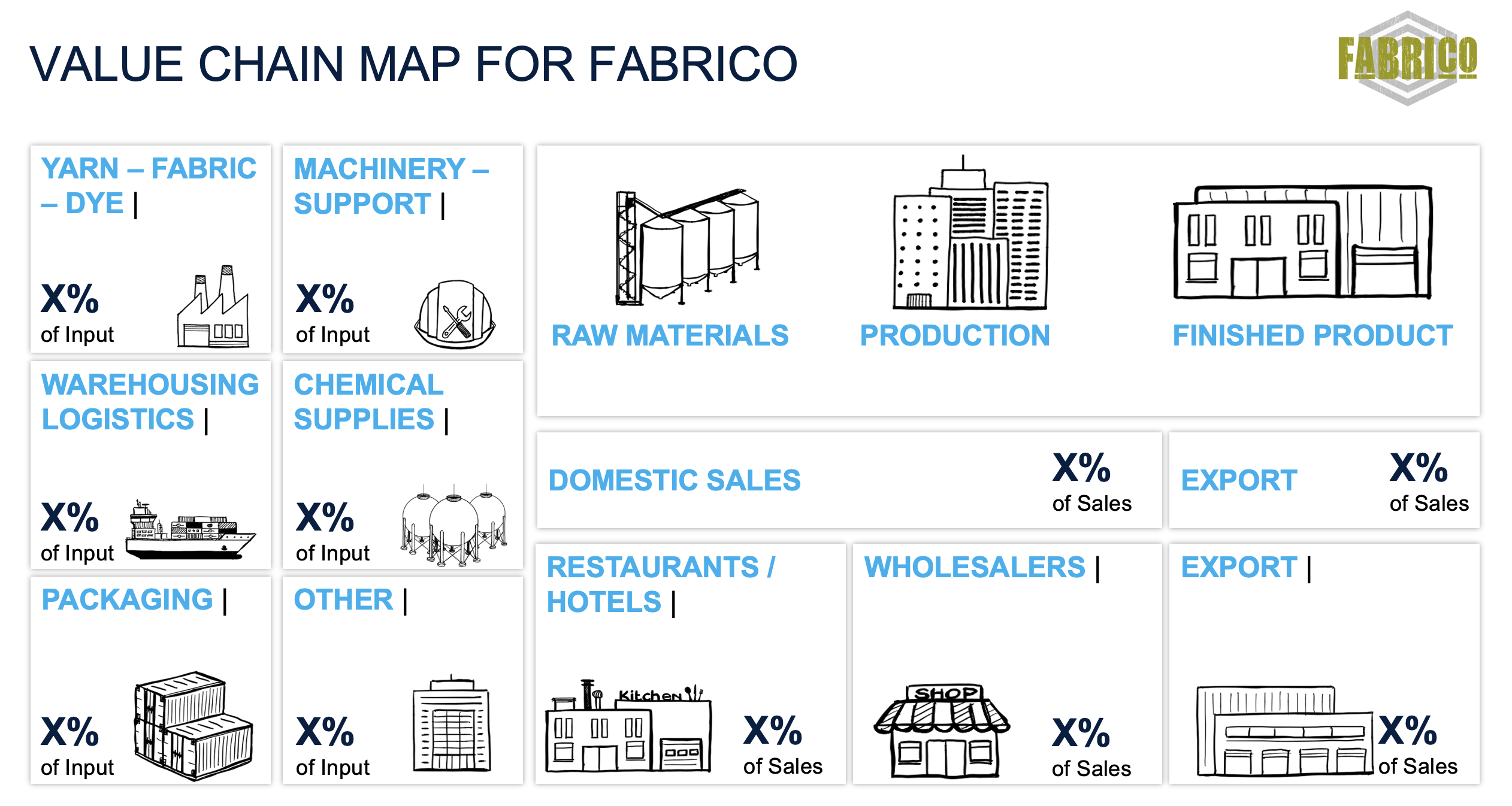

The value chain for FabriCo involves a series of activities that add value to its textile products, from the sourcing of raw materials to the delivery of finished goods to customers. Here is an overview of the various stages in FabriCo’s value chain:

- Raw material sourcing – FabriCo begins by sourcing raw materials such as cotton, wool, or synthetic fibers from suppliers who meet their sustainability and quality standards.

- Manufacturing – FabriCo then uses state-of-the-art equipment and manufacturing processes to produce textiles, including spinning, weaving, dyeing, and finishing.

- Quality control – At each stage of the manufacturing process, FabriCo conducts quality control checks to ensure that its products meet the highest standards of quality and durability.

- Product design – FabriCo’s team of expert designers work closely with clients to create custom textile solutions that meet their unique needs and requirements.

- Prototyping and testing – FabriCo creates prototypes of its textile products for clients to test and provide feedback on, to ensure that the final product meets their specifications.

- Packaging – FabriCo packages its textile products using eco-friendly materials and efficient packaging methods, to minimize waste and reduce its carbon footprint.

- Distribution and logistics – FabriCo partners with transport and logistics suppliers to ensure that its products are delivered to customers on time and in good condition.

- Customer service – FabriCo provides exceptional customer service and support, with a dedicated team that is available to answer questions, provide support, and address any concerns.

- Sustainability and social responsibility – FabriCo is committed to sustainability and social responsibility, and works with suppliers and clients who share its values. The company also supports local charities and initiatives that promote economic development and social welfare in its community.

By focusing on each stage of its value chain, FabriCo is able to create high-quality, sustainable, and socially responsible textile products that meet the needs of its clients and contribute to the growth of its business and community.

Information

Information

According to the Texland Textile and Clothing Association, the textile industry in Texland relies on imports for a significant portion of the fabric used in production. The exact percentage can vary depending on the specific segment of the industry and the type of fabric being used, but in general, it is estimated that around 70-80% of the fabric used in the Texland textile industry is imported.

This reliance on imported fabric is partly due to the fact that Texland does not have a large domestic textile production capacity, and also because some types of fabrics are not readily available or cost-effective to produce domestically.

However, the Texland government has been taking steps to develop the local textile industry and increase the use of local materials, such as cotton and wool, in textile production. This includes investing in the modernization of textile mills, increasing research and development efforts, and providing support and incentives for local textile manufacturers.

One of the main stumbling stones for local textile manufacturers is the lack of affordable financing to setup their operations. Current suppliers have indicated that they could grow their business significantly if financing was to be organized as they are currently limited in their ability to invest in equipment and technology, as well as having limited production capacity, which hinders them from competing with established fabric providers abroad.

- Fabric Suppliers – 209 Suppliers

25% of Cost of Goods Sold (COGS) [30% Domestic]- These are suppliers who provide the raw fabric materials that FabriCo uses to produce its textile products.

- Main Characteristics: payment terms of 105-120 days

- Yarn Suppliers – 100 Suppliers

20% of Cost of Goods Sold (COGS) [30% Domestic]- These are suppliers who provide the yarns that FabriCo may use in the production of its textiles.

- Main Characteristics: payment terms of 60 days

- Dye Suppliers – 13 Suppliers

10% of Cost of Goods Sold (COGS) [25% Domestic]- These are suppliers who provide the dyes and colorants used to add color to fabrics and textiles.

- Main Characteristics: payment terms of 90 days

- Machinery Suppliers – 13 Suppliers

15% of Cost of Goods Sold (COGS) [35% Domestic]- These are suppliers who provide the equipment and machinery used in FabriCo’s manufacturing processes.

- Main Characteristics: payment terms of 30 days

- Maintenance and Repair Suppliers – 11 Suppliers

5% of Cost of Goods Sold (COGS) [95% Domestic]- These are suppliers who provide maintenance and repair services for FabriCo’s equipment and machinery.

- Main Characteristics: payment terms of 30 days

- Warehousing, Transport, and Logistics Suppliers – 6 Suppliers

10% of Cost of Goods Sold (COGS) [60% Domestic]- These are suppliers who provide warehousing, transportation, and logistics services for FabriCo’s products, such as shipping and freight forwarding.

- Main Characteristics: payment terms of 15-60 days

- Chemical Suppliers – 180 Suppliers

5% of Cost of Goods Sold (COGS) [25% Domestic]- These are suppliers who provide the chemicals and other materials used in the production of FabriCo’s textiles, such as finishing agents and cleaning supplies.

- Main Characteristics: payment terms of 30 days

- Packaging Suppliers – 3 Suppliers

5% of Cost of Goods Sold (COGS) [87% Domestic]- These are suppliers who provide the packaging materials used to transport and store FabriCo’s products.

- Main Characteristics: payment terms of 30-60 days

-

Research and Development, as well as Sustainability Suppliers – 392 Suppliers

5% of Cost of Goods Sold (COGS) [100% Domestic]- These are suppliers who provide research and development services for FabriCo, such as testing new materials or developing new production processes.

- These are suppliers who provide sustainable and eco-friendly materials and services that align with FabriCo’s commitment to environmental responsibility.

- Main Characteristics: payment terms of 45 days

- Restaurants / Hotels (Chains)

9% of Sales- 1091 Clients

- Key Characteristics: 30 day Payment Term

- Wholesalers

39% of Sales- Through 35 distributors

- Serving 40.000 retailers

- Key Characteristics: 60 day Payment Term

- Export

52% of Sales- 120 Clients

- Mainly in Europe, some in the Americas and Asia

- Key Characteristics: on average 60 day Payment Term (ranging from 30-90 days)

Dear valued suppliers,

We are excited to announce that FabriCo is moving towards a more efficient and effective supply chain management system by implementing supplier portals that are even accessible via your mobile phone.

Our supplier portal will provide you with real-time access to critical information on purchase orders, order status, delivery schedules, and enables you to create invoices and see payment information all from the convenience of your mobile device. This move towards a mobile-friendly supplier portal is part of our ongoing commitment to improving our supplier management processes, as we strive to build stronger relationships with our valued partners.

We believe that this new system will enable us to communicate and collaborate with our suppliers more effectively and efficiently, which will ultimately improve the performance of our supply chain. By reducing the need for manual communication and increasing transparency, we expect to see increased accuracy, faster turnaround times, and improved delivery schedules.

By entering the invoices directly in this new supplier portal, invoices will be approved immediately by means of three-way match between the original purchase order, the digital goods receipt, and the invoice. This enables you to follow the approval process and increase your visibility on payment dates.

We are excited to move forward with this new system, and we look forward to working with you to make our partnership stronger than ever. If you have any questions or concerns about this new system, please do not hesitate to contact us.

Thank you for your continued support.

Sincerely,

Procurement Head | FabriCo